Revolutionary Cartridge‑Free Printing

❤️ Click here: Espon bottle dating site

Also, the format and space constraints of a journal article do not allow for the elaboration and illustrations necessary to make a key function fully Jones 1971b. An additional Shipping and Handling fee will apply to shipments going to Alaska, Hawaii or Puerto Rico.

This is also pointed out on the image above; click to enlarge. Consult page for more information on and pictures of these type bottles. See the page 4.

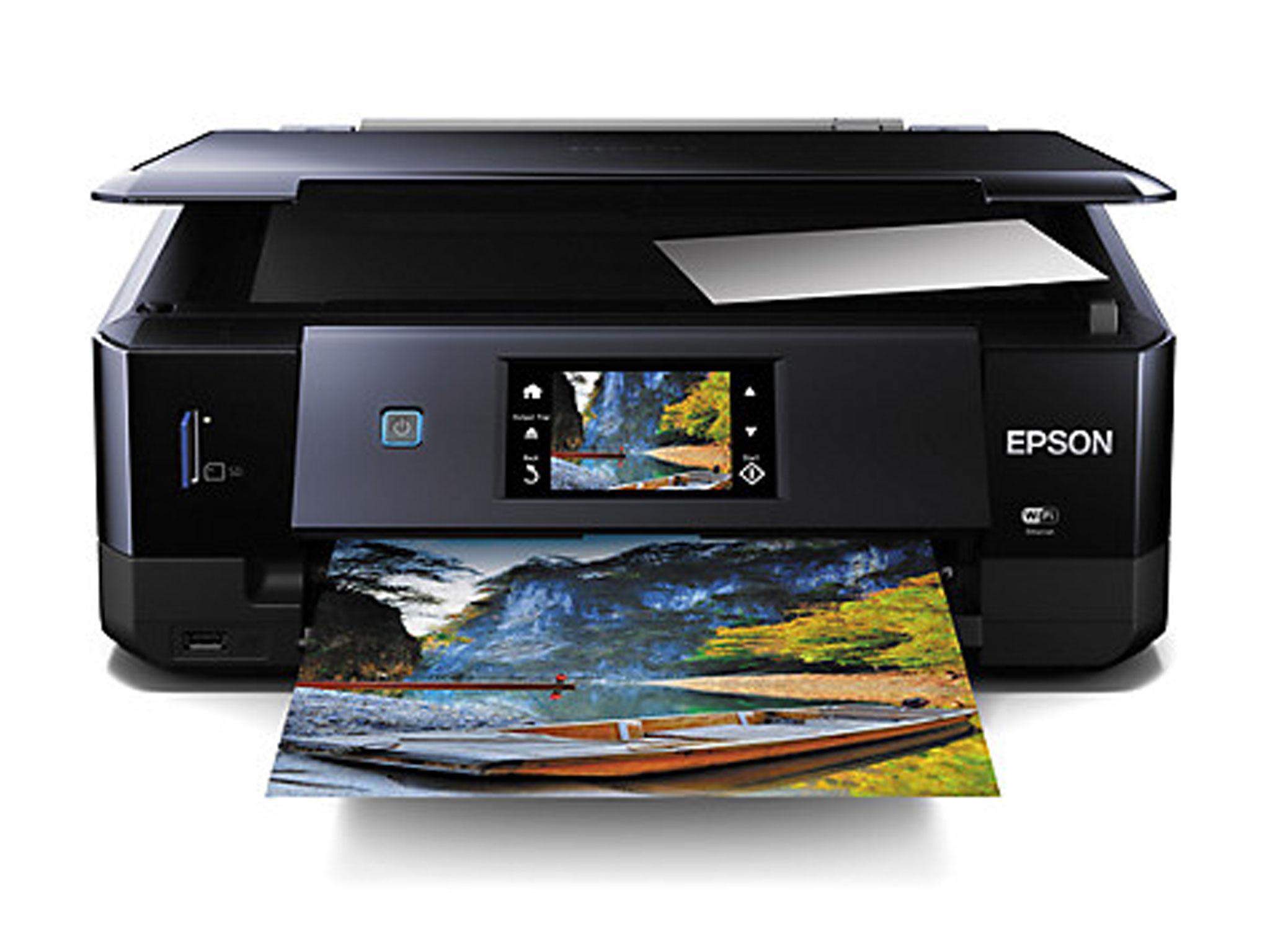

Revolutionary Cartridge‑Free Printing - The base image below is of an late 19th to early 20th century barber bottle base with a very distinct blowpipe pontil scar with a little residual iron from the pontil rod.

Please be aware that in order to gain the maximum information about any particular bottle e. Unfortunately, the complexities of precisely dating bottles is beyond the scope of any simple key. A substantial amount of bottle type specific information must be reviewed by a user to increase the probability of dating accuracy. The information on this website will, however, usually produce a reliable manufacturing date range for a majority of American utilitarian bottles manufactured from the early 1800s to the mid-20th century. For the first time user of this site it is highly recommended that the following information be read prior to using the key below. First this cautionary note : Bottle dating is not a precise science! Using physical, manufacturing related diagnostic features, most utilitarian bottles can usually only be accurately placed within a date range of 10-15 years i. There are numerous reasons for this: 1. Like many industries making the leap from manual craftsman production to industrialization and automation, technological advances in bottle manufacturing were not immediately accepted by glass manufacturers or their workers. Acceptance often occurred over a period of many years or decades in some cases. This makes some diagnostic characteristics better than others for dating. This will be noted where known. We can always have some indication of a starting date for a technique if we can find who first put the idea into practice. But any technique, once developed, can be used right up to the present - as many collectors know who have been so unfortunate as to rely too heavily on a popular termination date as sure evidence of true antiquity... In short, there was and is nothing to stop a glassmaker from using an obsolete method in the production of a bottle. The shift to the fully automated bottle machine from mouth-blown and some semi-automatic methods in the early 20th century is the classic example Toulouse 1967, 1969a. See the page 4. The same bottle could have been recycled and reused many times for many years before finally being discarded - entire or broken Busch 1987. This was almost universal with many beverage bottle types e. The bottle pictured to the right has a Wait's Liver and Kidney Bitters label pasted over the embossing of a Star Kidney and Liver Bitters bottle! The author has also seen Star Bitters labels on Wait's bottles as well as both labels on the immensely period popular Hostetter's Stomach Bitters bottles! Reuse, of course, does not change the manufacturing date of the bottle itself, but care must be exercised when using the known date of one or a few bottles to date other items found from the same context. An example of this is the finding of a few pontil scarred utilitarian bottles among otherwise late 19th or early 20th century refuse. It is unlikely that this bottle was made during the same era, but instead was reused for a lengthy period or otherwise retained until broken or discarded. Pontiled base fragments could also be from later produced which are described below. Other diagnostic tools must be used to date these items. Shape is more indicative of function - i. See the page for more information on the subject. All this adds to the fascination with bottle making, but makes systematic dating similar to solving Rubik's cube - ostensibly simple on the surface but complex in practice. That is the point of this website. A yet a couple additional factors to keep in mind in the dating of bottles... This Bottle Dating page and website in general is designed to address what the website author refers to as click for more information. Utilitarian items makes up the bulk of the bottles produced during the 19th century and first half of the 20th century. They are defined as: 1. Bottles intended to be used once to dispense the contained product without much hope of return, though as noted in 4 above, many types of bottles were commonly reused during the 19th and early 20th centuries; or 2. Produced during the era where all bottles were an relatively rare and cherished commodity to be discarded only when broken i. Utilitarian items include and since they were intended to be reused by the purchaser and have been observed to follow well the dating guidelines, though there are some manufacturing timeframe differences with canning jars. Click to view the typology page section devoted to that category. The beer bottle pictured to the above left is a classic example of a utilitarian bottle from the late 19th century that was typically reused. The dating guidelines found on these Dating Pages and the entire website do not always work well with what the author calls click for more information. This is because certain classes of these bottles were often made using glassmaking techniques from earlier times or with methods not used for utilitarian ware. For example, some bottle types which were intended to be kept indefinitely like the early 20th century barber bottle pictured to the right were produced with the use of pontil rods leaving telltale pontil scars on bottles into at least the early 20th century. The base image below is of an late 19th to early 20th century barber bottle base with a very distinct blowpipe pontil scar with a little residual iron from the pontil rod. Another exception example is that the bottles for expensive, low production liquors e. Many specialty bottles were imported from Europe, though that fact may be at times hard to impossible to ascertain. Specialty bottles can be, of course, occasionally found on historic sites usually fragments, but occasionally intact but can rarely be used to help date the site because of the diagnostic problems and issues noted above. Having stated the above, there are still many diagnostic features or characteristics that provide a high probability of both dating and typing a bottle with some precision. A key concept in historic bottle dating is the high probability i. The general probability estimates noted on this website are based on a merging of reliable references with empirical observations made by this site's affiliated consulting experts see the page and the author who have been students of historic bottle dating and identification for many years. N otes on embossing, labeling, and existing research Raised embossing and when present, paper labeling on a bottle can frequently provide important details to refine the probable manufacturing date range if information exists for the company that either manufactured the bottle i. For example, the early mineral water bottle pictured here is known to date between 1850-1851 based on the information provided by the embossing company name embossed on the pictured side and the glass maker - Union Glass Works - embossed on the reverse and complimentary research done by collectors Markota 1994. Researched historical information of variable depth and quality exists for thousands of different - typically embossed - bottles. Published works generally cover either a particular city, region, or category of bottles. See the page for more information. For a large majority of embossed and unembossed bottles, however, there is little or nothing formally published on the details of their origins. Only a relative few geographic areas or areas of collecting interest have received more than cursory historical treatment and the majority of this is due to the efforts of collectors. Unfortunately, it is likely that the majority of bottles produced during the 19th century have little or no information still existing today that would allow for substantive research. Time has taken its toll on records, of course, but much of what happened in the past was simply not documented well or at all as with most endeavors of common people in the past. Still all true today. This body of information will be utilized and extrapolated to make dating and typing estimates for the majority of bottles for which there is either no specific company or glass maker information available or such is not possible to determine because the bottles are unmarked i. To the authors knowledge, the first and only serious attempt at using a key to date American bottles was done in a 1970 Historical Archaeology journal article entitled A Dating Key For Post-Eighteenth Century Bottles by T. Stell Newman Newman 1970. Newman's key made a noble attempt at simplifying bottle dating, but is weakened by the fact that the subject is much too complex to be conducive to such a simple approach by itself. Also, the format and space constraints of a journal article do not allow for the elaboration and illustrations necessary to make a key function fully Jones 1971b. This website is designed to have the informational depth, pictures, and illustrations necessary to solve the problems of the Newman key though his warning still holds though hopefully less so. This entire website is essentially a key to the dating and typing of bottles. Though long out of print it is still widely available through internet used book sites, eBay®, and in used book stores. Before jumping into the key, it must again be emphasized that no single key can get a user to an absolutely precise date for any bottle. The best the following key can do is get a user to a reliably close dating range estimate. Other information on this website usually must be reviewed to fine tune the information about a specific bottle. In addition, other references beyond the scope of this website usually must be consulted to get as complete of a dating and typing story as is possible for any given bottle. Keep this all in mind as you progress through the key which follows and on into the other website pages............. Starting with , follow through the questions as suggested. There is frequent hyper-linking between the diagnostic characteristics and terminology listed on this page and other website pages. This is done to allow the user to get more information or clarification as they proceed through the key. When a dating sequence dead ends, it will be noted and other website pages suggested and hyperlinked for the user to consult. The three questions found on this page below answer several basic questions about a given bottle. Answers to these questions will then direct a user to one of the two additional dating pages which are extensions of this key for the two major classes of bottles - mouth-blown bottles and machine-made bottles. For examples of how to use this dating key see the page. This page guides a user through the key for seven different type and age bottles with several being side-by-side comparisons of very similar bottles of different eras. This page also shows how other portions of this website can provide information pertinent to the bottle in question. See the page for more information about the author and contributors. For brevity, most of the specific references are not noted in the key's narratives. They are noted on the other website pages which expand on the information summarized in the key. If you know your bottle is machine-made click to move directly to that page. If you know your bottle is mouth-blown aka hand-made click to move directly to that page. If unsure about what embossing or vertical side mold seams picture below are, click on to see this sub-page for a illustration and explanation of these and many other key bottle related physical features. Return back to this page by closing the Bottle Morphology page. For expanded information on body mold seams and embossing review the page. Vertical side mold seam on the neck of a beer bottle ending well below the finish, indicating that it was at least partially handmade - ca. YES - The bottle has embossing or visible vertical side mold seams somewhere on the body between the and the base of the or lip. A bottle may have mold seams but no embossing, but all embossed bottles were molded and have mold seams even if they are not readily apparent. If so, move to below. NO - The bottle has NO embossing and NO apparent vertical side mold seams on the body, shoulder, or neck. If necessary, look very closely at the bottle shoulder - the best location to see vertical side seams on mouth-blown and most machine-made bottles - in good light with a hand lens to see if there is at least some faint evidence of where the mold edges came together. Often the vertical side mold seams are evidenced by very faint changes in glass density in lines where one would expect mold seams to be. For additional help review the page. The concept is that the higher the side mold seam on the bottle the later it was made - at least in the era from the early to mid 19th century until the first few decades of the 20th century. Kendrick's explains in the text pages 45-47 that... It is true that the mold seams can be used like a thermometer to determine the approximate age of a bottle. The closer to the top of the bottle the seams extend, the more recent was the production of the bottle. The chart accompanying this statement notes that bottles made before 1860 have a side mold seam ending on the shoulder or low on the neck, between 1860 and 1880 the seam ends just below the finish, between 1880 and 1900 the seam ends within the finish just below the finish rim top lip surface , and those made after 1900 have mold seams ending right at the top surface of the finish, i. Although there are examples of bottles having mold seams that fit these date ranges properly, the issue of dating bottles is vastly more complicated than the simple reading of side mold seams. If it were that simple much of this website would be unnecessary! For example, the process that produces a tooled finish frequently erases traces of the side mold seam an inch or more below the base of the finish whereas the typical applied finish has the seam ending higher - right at the base of the finish Lockhart et. The reason this is noted here is that the concept keeps popping up in the literature of bottle dating and identification ranging from Sellari's books Sellari 1970:5 published shortly after Kendrick's book to as recent as Fike 1998:4 and Heetderk's 2002:15. It is also frequently noted by sellers on eBay® when describing their offerings. For a broader discussion of this subject see Lockhart, et al. If unsure about what the lip, rim, or finish of a bottle is, check the sub-page. If you need more information on this diagnostic feature - including various images - click the following link: Close-up of the finish lip of an Illinois Glass Co. The picture to the left shows both of these mold seams click to enlarge. Machine-made bottle making processes are described in much more depth on the page. If your bottle fits this description, click to move to the related webpage which allows the user to pursue more information on bottles produced almost totally in the 20th century by some type of automatic or semi-automatic bottle machine. The vast majority of U. Click to pursue more information on the Mouth-Blown Bottles portion of this key you will move to another webpage. Fire Polishing - Occasionally encountered machine-made bottles may have fire polished finish rims - a process which eradicated evidence of the seam on the rim of the bottle. These bottles will not have the side mold seam proceeding from the upper finish side over and onto the rim itself. These bottles will, however, have the vertical side mold seam progressing all the way to the very top of the finish side, just not onto the rim. They will also have other machine-made characteristics as described on the page. In the experience of the website author, these machine-made bottles are rarely encountered and likely a function of early machine-made wares 1905 to 1920s that had less precise mold fitting and resulted in the need for fire polishing to enable proper closure. Milk Bottles - Many milk bottles made with machines from the very early 1900s into at least the 1940s resulted in vertical side mold seams that gradually fade out on the neck distinctly below the base of the finish. These milk bottles will also virtually always have a diagnostic mold seam horizontally encircling the outside of the finish and a distinct on the base. Click on the image to the right to view both mold seam features pointed out on a press-and-blow machine manufactured milk bottle made by the Pacific Coast Glass Company San Francisco, CA. For more information and images of typical milk bottles from that era, including an explanation of why the side mold seams fade out on the neck, go to the typology page. If your bottle is a milk bottle that fits this description, click to move to the Machine-made bottles dating page for more possible dating refinement and to pursue more information. The image to the left is a close-up of the shoulder, neck and finish of a small Sheaffers ink bottle click to enlarge for more detail. The image shows the vertical side mold seam ending on the outside edge of the bead finish at a the upper portion of a induced horizontal mold seam that encircles the extreme outer edge of the finish. The side mold seam does not extend onto the top surface of the finish, i. These features are pointed out - and much more readable - on the larger hyperlinked image; click to view. The image to the right is a close-up of a small, medium green, machine-made ink bottle. As above, click on the image to view a larger and much more readable version with the various features pointed out. This termination of the side mold seam within the finish short of the rim Sheaffers ink or actually short of the finish itself green ink on these bottles makes it appear upon casual glance that these are mouth-blown bottles having either an Sheaffers or an green ink. However, both bottles are most certainly machine-made. The Sheaffers ink was made on the as indicated by the previously noted makers marking for the Owens-Illinois Glass Co. There is also no neck ring mold seam immediately below the finish like found on most Owens machine produced bottles and on a majority of all machine-made bottles. Instead, there is one located near the base of the neck indicating that the neck ring mold portion of the parison mold produced the finish, neck, and a portion of the shoulder. This is also pointed out on the image above; click to enlarge. The earlier green glass ink bottle is also certainly machine-made, most likely on an early semi-automatic, machine based on its crudeness and lack of a suction scar. It also has no neck ring mold seam immediately below the finish like found on most Owens machine produced bottles or on the majority of all machine-made bottles. Instead ,there is also one located near the base of the neck indicating that the neck ring mold portion of the parison mold produced the finish, neck, and a portion of the shoulder. This is also pointed out on the image above; click to enlarge. Both these ink bottles also exhibit no sign of the concentric, horizontal finishing tool induced marks that would be present on a mouth-blown finish. These bottles are discussed in more detail in the ink bottle section of the typology page. If your bottle is an ink fitting the descriptions above, click to move to the Machine-made bottles dating page for more possible dating refinement and to pursue more information. Bottle DOES NOT Have Vertical Side Mold Seams. The concentric rings are not always as obvious as the picture shows click to enlarge and sometimes not visible, though if present it is a conclusive diagnostic feature. Turn-mold bottle body showing faint concentric rings. YES - This bottle was produced in a which was also known in the glass industry as a paste-mold. All turn-mold bottles are round in cross section and unless stained, will usually have a polished looking sheen to the glass surface. Go to for a possible dating refinement based on the method of finish application, though some of the diagnostic features can be masked by the turn-mold production process. This bottle is probably or. These two manufacturing types can be hard to differentiate from each other, though free-blown bottles are almost always round or oval in cross-section and have lines that are not sharp i. Most free-blown bottle date prior to 1850 and can be much older. Dip mold bottles usually date prior to 1865-1870 but can also be much older back to early 18th century at least. A user may move to for one additional dating attribute based on pontil scars, though all these datable attributes free-blown, dip mold, and pontil scars overlap significantly. Consult page for more information on and pictures of these type bottles. Click to move to the portion of the Dating key for Mouth-blown bottles new webpage. Click to move to the portion of the Dating key for Machine-made bottles new webpage. Copyright © 2018 Bill Lindsey. Viewers are encouraged, for personal or classroom use, to download limited copies of posted material. No material may be copied for commercial purposes. Author reserves the right to update this information as appropriate.

Epson local ink Epson original genuine ink Detail एप्सन असली और नकली इंक पहचान

For expanded information on body mold seams and embossing review the page. Other information on this website usually must be reviewed to fine tune the information about a civil bottle. Espon bottle dating site date night printable digital download bundle features gorgeous printables from one of our all-time favorite designers:. Instead ,there is also one located near the base of the neck indicating that the neck ring mold portion of the parison mold produced the finish, neck, and a idea of the shoulder. For example, the process that produces a tooled finish frequently erases traces of the side mold seam an inch or more below the base of the finish whereas the typical applied finish has the seam ending higher - right at the base of the finish Lockhart et. Difference For information or a written copy of the manufacturer's warranty, please contact us at: warranty contactcostco.